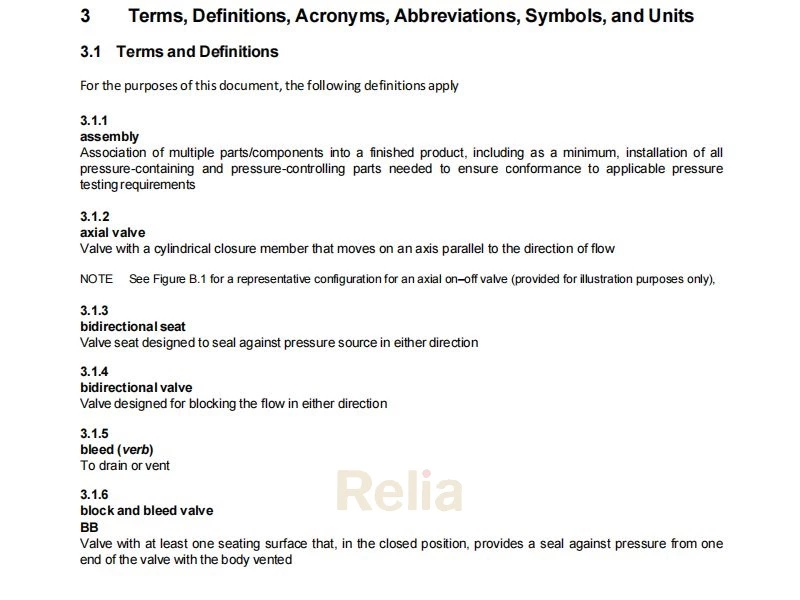

API 6D Bore Size for Full-opening Valves

API 6D Bore Size for Full-opening Valves and reduced-opening valves in inch and milimeter.

Table 1—API 6D Bore Size for Full-opening Valves

| NPS | DN | Minimum a Bore Size by Class, in. (mm)b | |||

| Class 150 to 600 | Class 900 | Class 1500 | Class 2500 | ||

| ½ | 15 | 0.50 (12.7) | 0.50 (12.7) | 0.50 (12.7) | 0.50 (12.7) |

| ¾ | 20 | 0.75 (19.0) | 0.75 (19.0) | 0.75 (19.0) | 0.75 (19.0) |

| 1 | 25 | 0.98 (25.0) | 0.98 (25.0) | 0.98 (25.0) | 0.98 (25.0) |

| 1¼ | 32 | 1.25 (31.8) | 1.25 (31.8) | 1.25 (31.8) | 1.25 (31.8) |

| 1½ | 40 | 1.50 (38.0) | 1.50 (38.0) | 1.50 (38.0) | 1.50 (38.0) |

| 2 | 50 | 1.93 (49.0) | 1.93 (49.0) | 1.93 (49.0) | 1.65 (42.0) |

| 2½ | 65 | 2.44 (62.0) | 2.44 (62.0) | 2.44 (62.0) | 2.05 (52.0) |

| 3 | 80 | 2.91 (74.0) | 2.91 (74.0) | 2.91 (74.0) | 2.44 (62.0) |

| 4 | 100 | 3.94 (100.0) | 3.94 (100.0) | 3.94 (100.0) | 3.42 (87.0) |

| 6 | 150 | 5.91 (150.0) | 5.91 (150.0) | 5.67 (144.0) | 5.16 (131.0) |

| 8 | 200 | 7.91 (201.0) | 7.91 (201.0) | 7.55 (192.0) | 7.04 (179.0) |

| 10 | 250 | 9.92 (252.0) | 9.92 (252.0) | 9.41 (239.0) | 8.78 (223.0) |

| 12 | 300 | 11.93 (303.0) | 11.93 (303.0) | 11.30 (287.0) | 10.43 (265.0) |

| 14 | 350 | 13.15 (334.0) | 12.67 (322.0) | 12.40 (315.0) | 11.50 (292.0) |

| 16 | 400 | 15.16 (385.0) | 14.69 (373.0) | 14.17 (360.0) | 13.11 (333.0) |

| 18 | 450 | 17.16 (436.0) | 16.65 (423.0) | 15.98 (406.0) | 14.72 (374.0) |

| 20 | 500 | 19.17 (487.0) | 18.54 (471.0) | 17.87 (454.0) | 16.50 (419.0) |

| 22 | 550 | 21.18 (538.0) | 20.55 (522.0) | 19.69 (500.0) | — |

| 24 | 600 | 23.19 (589.0) | 22.44 (570.0) | 21.50 (546.0) | — |

| 26 | 650 | 24.92 (633.0) | 24.29 (617.0) | 23.38 (594.0) | — |

| 28 | 700 | 26.93 (684.0) | 26.18 (665.0) | 25.23 (641.0) | — |

| 30 | 750 | 28.94 (735.0) | 28.03 (712.0) | 27.00 (686.0) | — |

| 32 | 800 | 30.66 (779.0) | 29.92 (760.0) | 28.74 (730.0) | — |

| 34 | 850 | 32.68 (830.0) | 31.81 (808.0) | 30.50 (775.0) | — |

| 36 | 900 | 34.41 (874.0) | 33.66 (855.0) | 32.24 (819.0) | — |

| 38 | 950 | 36.42 (925.0) | 35.59 (904.0) | — | — |

| 40 | 1000 | 38.43 (976.0) | 37.63 (955.8) | — | — |

| 42 | 1050 | 40.16 (1020.0) | 39.61 (1006.0) | — | — |

| 48 | 1200 | 45.90 (1166.0) | 45.24 (1149.0) | — | — |

| 54 | 1350 | 51.65 (1312.0) | — | — | — |

| 56 | 1400 | 53.54 (1360.0) | — | — | — |

| 60 | 1500 | 57.40 (1458.0) | — | — | — |

| FOOTNOTES a There is no upper size limit for a valve bore. b The millimeter dimension is the inch dimension multiplied by 25.4 and rounded to one decimal place. “—“ = No identified minimum bore. |

|||||

4.5 Valve Bore

4.5.1 Full-opening Valves

Full-opening valves shall be unobstructed in the fully opened position and shall have an internal minimum circular opening for categorizing bore size as specified in Table 1. When pipe is used in the construction of the valves, the pipe shall meet the tolerances of the applicable pipe specification. Closure member and seat dimensions shall meet Table 1.

Valves with a noncircular opening through the closure member shall not be identified as full opening.

4.5.2 Reduced-opening Valves with Circu lar Opening

Reduced-opening valves with a circular opening through the closure member shall be supplied with a minimum bore as follows:

― valves NPS 4 (DN 100) to NPS 12 (DN 300): one size below nominal size of valve with bore according to Table 1,

― valves NPS 14 (DN 350) to NPS 24 (DN 600): one or two sizes below nominal size of valve with bore according to Table 1.

― valves sizes less than NPS 4 (DN 100) or greater than NPS 24 (DN 600) in conformance with K.3

EXAMPLE An NPS 16 (DN 400) Class 1500 reduced-opening ball valve has an allowable minimum bore of 11.30 in. (287.0 mm).

4.5.3 Non-standard Opening Valves—Other Bore Sizes

A valve with a non-standard opening that does not conform to 4.5.1 or 4.5.2 shall still satisfy all applicable requirements of this specification.

These valves shall include, but not be limited to the following:

― axial valves (see Figure B.1)

― check valve axial flow (see Figure B.6)

― check valve, long pattern, typical dual-plate wafer-type (See Figure B.9)

― check valve, piston (See Figure B.10)

― swing check valve, reduced opening (See Figure B.11)

― check valve, short pattern, single-plate wafer-type (See Figure B.12)

― plug valve (See Figure B.15)

NOTE Other valve configurations may apply.

Other bore and non-standard opening valve sizes shall conform to K.3