API 6D Annex H

API 6D Annex H: heat-treat equipment qualification covers temperature survey method for batch-type furnaces and temperature survey method for continuous-type furnaces.

Annex H

(normative)

Heat-Treat Equipment Qualification

H.1 Temperature Survey Method for Batch-type Furnaces

The furnace working zone shall be defined by the manufacturer. A temperature survey within the furnace working zone(s) shall be performed on each furnace at the maximum and minimum temperatures for which each furnace is being used.

For furnaces having a working zone less than or equal to 10 ft3 (0.3 m3), a minimum of three temperature sensors located either at the front, center and rear, or at the top, center and bottom of the furnace working zone shall be used.

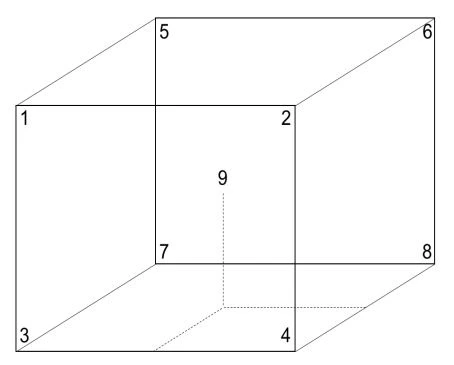

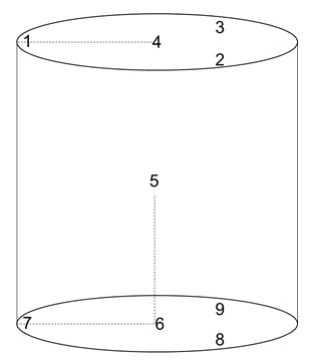

For furnaces having a working zone greater than 10 ft3 (0.3 m3) and not greater than 1125 ft3 (31.5 m3), a minimum of nine temperature sensors shall be used. For each additional 125 ft3 (3.5 m3) beyond 1125 ft3 (31.5 m3) of furnace working zone surveyed, at least one additional temperature sensors shall be used, up to 40 temperature sensors. The first nine thermocouples shall be located as per Figure H.1 and Figure H.2. Each additional temperature sensors location shall be equally spaced in the central additional working zone volume.

NOTE Alternative recognized industry standards such as SAE AMS-2750 or SAE AMS-6875, may be used if the furnace thermal uniformity survey (TUS) and furnace instrument calibration requirements in 6.7 are satisfied.

Figure H.1—Thermocouple Locations—Rectangular Furnace (Working Zone)

Figure H.2—Thermocouple Locations—Cylindrical Furnace (Working Zone)

After insertion of the temperature-sensing devices, readings shall be taken at least once every three minutes to determine when the temperature of the furnace working zone approaches the bottom of the temperature range being surveyed.

Once the furnace temperature has reached the set-point temperature, the temperature of all test locations shall be recorded at two-minute intervals, maximum, for at least 10 minutes. Then, readings shall be taken at five-minute intervals, maximum, for enough time (at least 30 minutes) to determine the recurrent temperature pattern of the furnace working zone.

H.2 Temperature Survey Method for Continuous-type Furnaces

Furnaces used for continuous heat treatment shall be validated in conformance with procedures specified in SAE AMS 2750 or SAE AMS-H-6875.