API 624: Type Testing of Rising Stem Valves Equipped with Graphite Packing for Fugitive Emissions

API 624 standard specifies the requirements and acceptance criteria(100 ppmv)for fugitive emission type testing of rising and rising-rotating stem valves equipped with packing previously tested in accordance with API 622. Packing shall be suitable for use at service temperatures-29 °C to 538 ℃(-20 °F to 1000 °F). The type testing requirements contained herein are based upon elements of EPA Method 21.

5 Type Testing

5.1 The test medium used shall be methane 97 % minimum purity.

Caution—Methane used during testing is a pressurized flammable gas which requires that appropriate safety measures be taken.

5.1.1 Testing of valves is potentially hazardous and it is essential that the safety of personnel be given prime consideration. Given the nature of this test, hazardous release of pressurized gas could occur. Adequate shields or barriers in the area of the test enclosure and other appropriate means for the protection of personnel shall be provided.

5.1.2 The test facilities shall be designed to ensure that all the test conditions are conducted in a safe and protected environment. It is the responsibility of the testing facility to analyze the hazards resulting from the pressure and temperatures and take proper safety precautions. All applicable safety regulations shall be complied with.

5.1.3 All equipment shall have appropriate certification that verifies its suitability to withstand the minimum and maximum pressures and temperatures in the testing environment.

5.1.4 Hoses or pipes used for inlet and outlet supply of methane shall be suitable for maximum pressures and temperatures. Where hoses are used, appropriately designed restraints shall be used to prevent hose detachment from the test rig in the event that a blow-out occurs.

5.1.5 All testing shall be in accordance with local and national codes and regulations.

5.2 The stem orientation for a test valve shall be vertical.

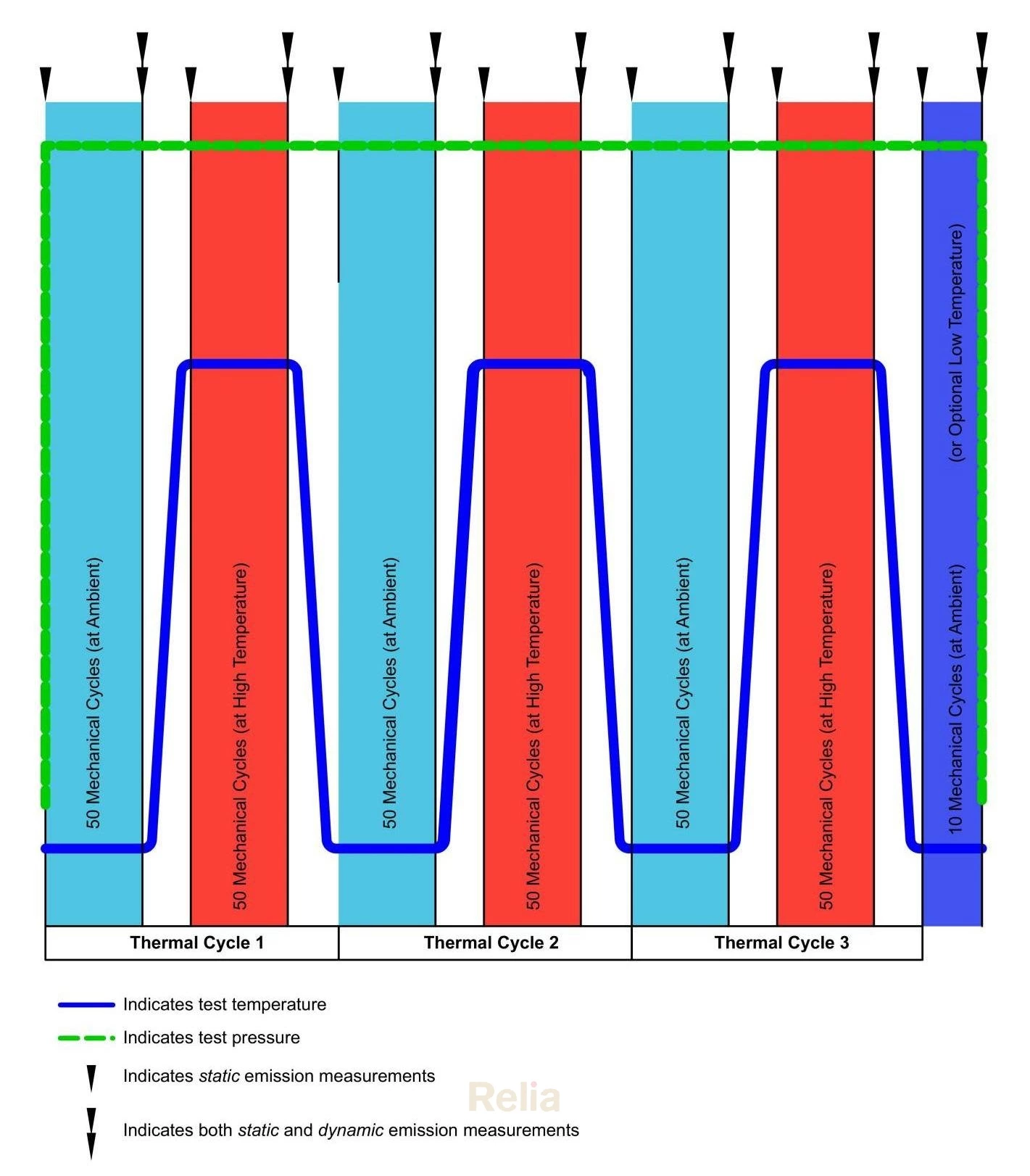

5.3 Valves shall be subjected to a total of 310 mechanical cycles and 3 thermal cycles per Figure 1. Mechanical cycling shall begin with the valve at ambient temperature. An optional low temperature test at –29 °C (–20 °F) may be performed if requested by the purchaser (see Figure 1).

5.4 The valve shall be heated using an internal heat source or an external heat source such as electric heating blanket, coils, or other suitable equipment or an appropriate internal heat source.

5.5 The elevated test temperature shall be 260 °C (500 °F) ±5 percent.

5.6 The test pressure shall be the lower of 41.4 barg (600 psig) or the maximum allowable pressure at 260 °C (500 °F) per ASME B16.34 for the applicable material group and shall be held constant throughout the test.

Figure 1—Valve Cycling

5.7 The test valve may be equipped with a method of actuation capable of mechanically cycling the valve. The method of actuation should not impose additional side loads on the stem or packing. Running torque values shall be recorded on the first and last cycle of testing.

5.8 Static and dynamic stem leakage measurements shall be taken. See Figure 1.

5.8.1 Leak measurements shall be conducted in still air. Shielding potential leak paths from environmental impacts with a foil enclosure shall be employed during testing. The foil enclosure shall include the stem outside diameter and packing outside diameter.

5.8.2 Leak measurements of the body-bonnet connection and auxiliary connections shall be sniffed. Leakage from body-bonnet and auxiliary connections can affect leak measurement readings and shall be corrected prior to continuation of the test and noted in the report. The detector probe speed shall be approximately 25 mm (1 in.) per second for the bonnet. The instrument shall be adjusted to compensate for the background methane level.

5.8.3 The static/dynamic leakage shall be recorded after a time delay of twice the response time of the instrument.

5.9 The valve shall be equipped with thermocouples for monitoring the temperature during testing. The temperature shall be monitored and recorded at two locations (see Figure 2).

5.9.1 TC-1—affixed to the stuffing box. The thermocouple affixed to the stuffing box shall control the test temperature.

5.9.2 TC-2—at the external body adjacent to the flow path shall be a reference measurement.

5.9.3 TC-2—shall be equal to or greater than TC-1.

5.10 Packing adjustment during type testing is not permitted.

6 Acceptance Criteria

The Fugitive Emissions Test Report in Annex A shall indicate “pass” when the measured leakage throughout the test does not exceed 100 ppmv.