API 623: Steel Globe Valves—Flanged and Butt-welding Ends, Bolted Bonnets

Steel Globe Valves—Flanged and Butt-welding Ends, Bolted Bonnets

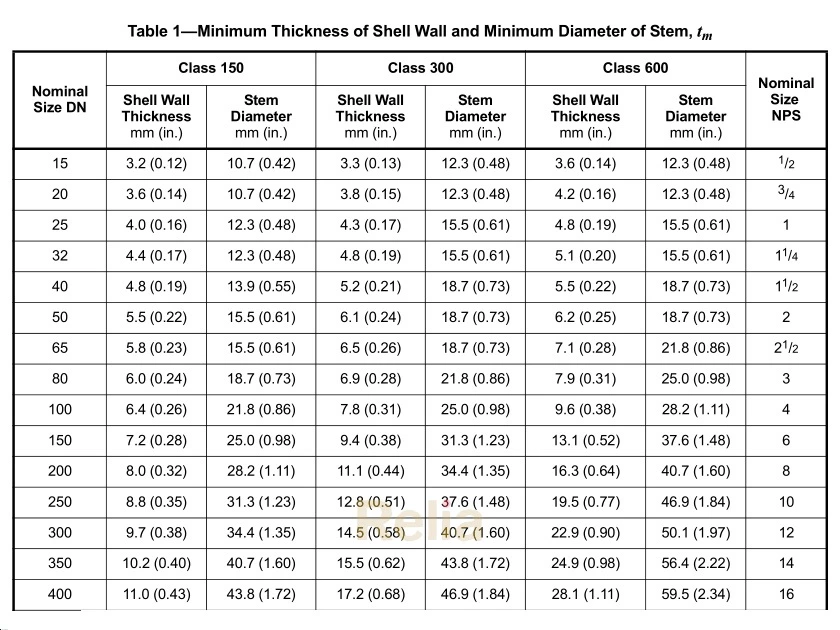

API 623 standard specifes the requirements for a heavy-duty series of bolted bonnet steel globe valves for petroleum refnery and related applications where corrosion, erosion, and other service conditions would indicate a need for heavy wall sections and large stem diameters.

API 623 standard sets forth the requirements for the following globe valve features:

— bolted bonnet;

— pressure seal bonnet;

— outside screw and yoke;

— rotating rising stems and nonrotating rising stems;

— rising handwheels and nonrising handwheels;

— straight pattern, y-pattern, right-angle;

— stop-check (nonreturn type globe valves in which the disc may be positioned against the seat by action of the stem but is free to rise as a check valve due to fow from under the disc when the stem is in a full or partially open position);

— plug, narrow, conical, ball, or guided disc;

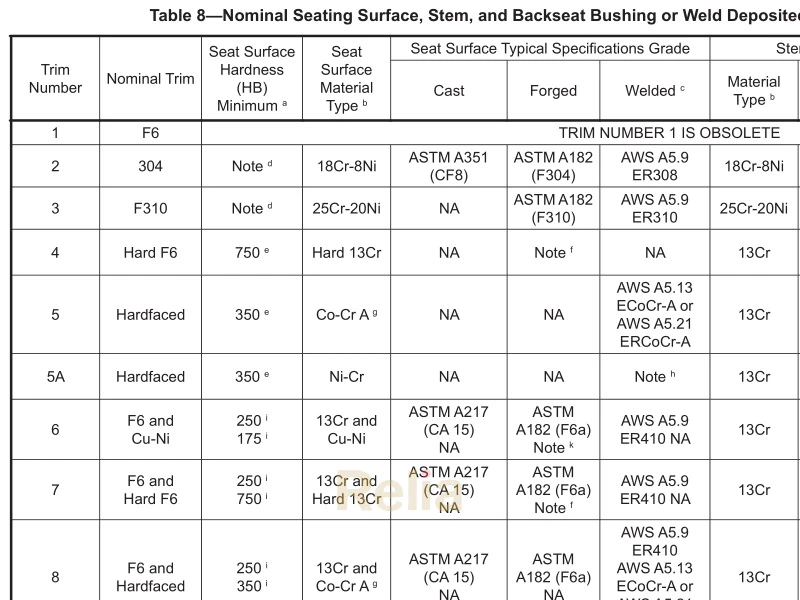

— metallic seating surfaces;

— fanged or butt-welding ends.

API 623 covers valves of the nominal pipe sizes NPS:

— 2, 2 1 / 2 , 3, 4, 6, 8, 10, 12, 14, 16, 18, 20, 24;

corresponding to nominal pipe sizes DN:

— 50, 65, 80, 100, 150, 200, 250, 300, 350, 400, 450, 500, 600;

applies for pressure class designations:

— 150, 300, 600, 900, 1500, 2500.