API 602 Valve Wall Thickness

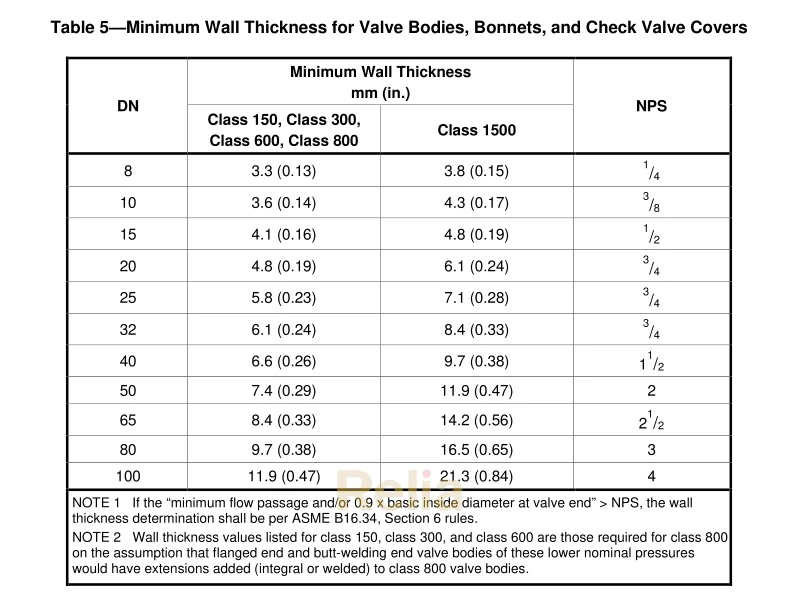

API 602 minimum wall thickness values for valve bodies, bonnets, and check valve covers shall be in accordance with the following table.

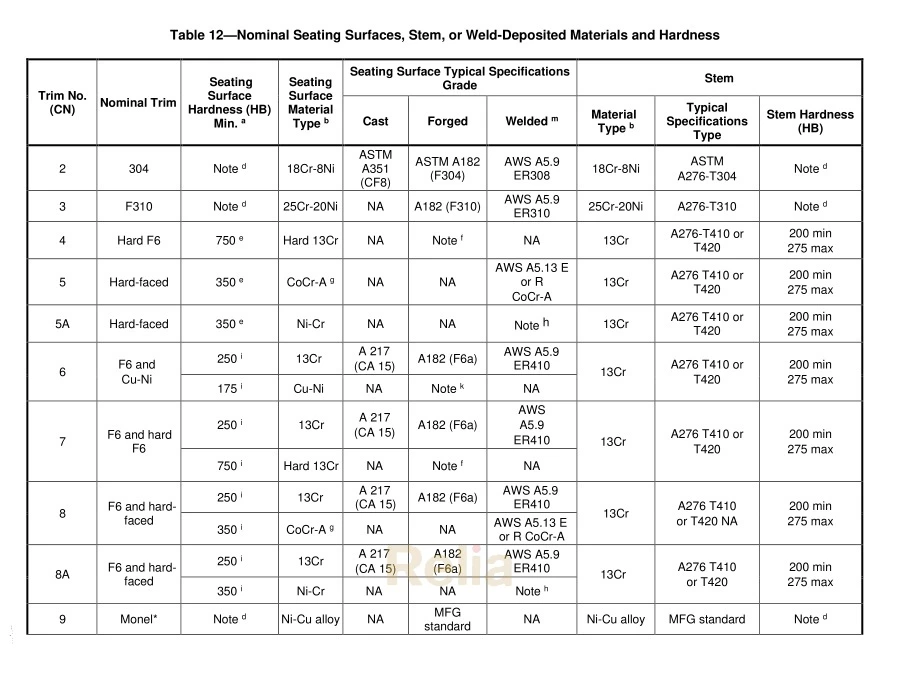

Table 5—Minimum Wall Thickness for Valve Bodies, Bonnets, and Check Valve Covers

| DN | Minimum Wall Thickness mm (in.) | NPS | |

| Class 150, Class 300, Class 600, Class 800 | Class 1500 | ||

| 8 | 3.3 (0.13) | 3.8 (0.15) | 1/4 |

| 10 | 3.6 (0.14) | 4.3 (0.17) | 3/8 |

| 15 | 4.1 (0.16) | 4.8 (0.19) | 1/2 |

| 20 | 4.8 (0.19) | 6.1 (0.24) | 3/4 |

| 25 | 5.8 (0.23) | 7.1 (0.28) | 3/4 |

| 32 | 6.1 (0.24) | 8.4 (0.33) | 3/4 |

| 40 | 6.6 (0.26) | 9.7 (0.38) | 1-1/2 |

| 50 | 7.4 (0.29) | 11.9 (0.47) | 2 |

| 65 | 8.4 (0.33) | 14.2 (0.56) | 2-1/2 |

| 80 | 9.7 (0.38) | 16.5 (0.65) | 3 |

| 100 | 11.9 (0.47) | 21.3 (0.84) | 4 |

NOTE 1 If the “minimum flow passage and/or 0.9 x basic inside diameter at valve end” > NPS, the wall thickness determination shall be per ASME B1 6.34, Section 6 rules.

NOTE 2 Wall thickness values listed for class 1 50, class 300, and class 600 are those required for class 800 on the assumption that flanged end and butt-welding end valve bodies of these lower nominal pressures would have extensions added (integral or welded) to class 800 valve bodies.

5.3 Wall Thickness

5.3.1 Except as provided for in 5.3.2 through 5.3.6, the minimum wall thickness values for valve bodies, bonnets, and check valve covers shall be in accordance with Table 5. The manufacturer—taking into account such factors as bonnet bolting loads, rigidity needed for stem alignment, valve design details, and the specified operating conditions— is responsible for determining if a larger wall thickness is required.

5.3.2 Valve body end connection minimum wall thickness shall be in accordance with 5.4.2, 5.4.3, 5.4.4, or 5.4.5 as applicable.

5.3.3 Extended body valves shall have body extension minimum wall thickness in accordance with Annex B.3.

5.3.4 Valves having bellows stem seals with a bellows enclosure shall have a bellows enclosure extension minimum wall thickness in accordance with Annex C.4.

5.3.5 The bonnet minimum wall thickness for gate or globe valves with bonnet extensions, excluding bellows enclosures, shall be in accordance with Table 6, based on the inside diameter of the extension.

5.3.6 The wall surrounding the packing chamber and stem hole shall have a local minimum wall thickness as specified in Table 6, based on the local inside diameter of the packing and stem hole. The minimum wall thickness shall not be less than the values indicated for an inside diameter of 1 5 mm (0.60 in.).