API 602 Trim Number Chart

All API 602 Trim Number, such as trim no. 2, 3, 4, 5, 5A, 6, 8, 9, 10, 12, 13, 14, 15, 16.... items include the stem, the wedge/disc seating surfaces, and the body or seat ring seating surfaces.

Table 12—API 602 Nominal Seating Surfaces, Stem, or Weld Deposited Materials and Hardness

| Trim No. (CN) | Nominal Trim | Seating Surface Hardness (HB) Min, a |

Seating Surface Material Type b |

Seating Surface Typical Specifications Grade |

Stem | ||||

| Cast | Forged | Welded m | Materia Type b |

Typical Specifications Type |

Stem Hardness (HB) |

||||

| 2 | 304 | Vote d | 8Cr-8N | ASTM A351 (CF8) |

ASTM A182 (F304) | AWS A5.9 ER308 |

18Cr-8Ni | ASTM A276-T304 |

Note d |

| 3 | F310 | Note d | 25Cr-20Ni | NA | A182 (F310) | AWS A5.9 ER310 | 25Cr-20Ni | A276-T310 | Note d |

| 4 | Hard F6 | 750 e | Hard 13Cr | NA | Note f | NA | 13Cr | A276-T410 or T420 | 200 min 275 max |

| 5 | Hard-faced | 350 e | CoCr-A g | NA | NA | AWS A5.13 E or R CoCr-A | 13Cr | A276 T410 or T420 |

200 min 275 max |

| 5A | Hard-faced | 350e | Ni-Cr | NA | NA | Note h | 13Cr | A276 T410 or T420 | 200 min 275 max |

| 6 | F6 and Cu-Ni | 250 | 13Cr | A 217 (CA 15) |

A182 (F6a) | AWS A5.9 ER410 |

13Cr | A276 T410 Or T420 | 200 min 275 max |

| 175i | Cu-Ni | NA | Note k | NA | |||||

| 7 | F6 and hard F6 | 250 i | 13Cr | A217 (CA 15) |

A182 (F6a) | AWS A5.9 ER410 |

13Cr | A276 T410 or T420 | 200 min 275 max |

| 750 i | Hard 13Cr | NA | Note f | NA | |||||

| 8 | F6 and hard- faced | 250 i | 13Cr | A217 (CA 15) |

A182 (F6a) | AWS A5.9 ER410 |

13Cr | A276 T410 or T420 NA |

200 min 275 max |

| 350 i | CoCr-A g | NA | NA | AWS A5.13 E or R CoCr-A |

|||||

| 8A | F6 and hard- faced | 250 i | 13Cr | A 217 (CA 15) |

A182 (F6a) | AWS A5.9 ER410 |

13Cr | A276 T410 or T420 |

200 min 275 max |

| 350 i | Ni-Cr | NA | NA | Note h | |||||

| 9 | Monel* | Note d | Ni-Cu alloy | NA | MFG standard | NA | Ni-Cu alloy | MFG standard | Note d |

Table 12—API 602 Nominal Seating Surfaces, Stem, or Weld Deposited Materials and Hardness (Continued)

| Trim No (CN) | Nominal Trim | Seating Surface Hardness (HB) Min.a |

Seating Surface Material Type b |

Seating Surface Typical Specifications Grade | Stem | ||||

| Cast | Forged | Welded m | Material Type b | Typical Specifications Type | Stem Hardness (HB) |

||||

| 10 | 316 | Note d | 18Cr-8Ni- Mo | A351 (CF8M) | A182(F316) | AWS A5.9 ER316 |

18Cr-8Ni-Mo | A276-T316 | Note d |

| 11 | Monel* and hard-faced | Note d | Ni-Cu alloy | NA | MFG standard | NA | Ni-Cu alloy | MFG standard | Note d |

| 3501 | Trim 5 or 5A | NA | NA | See Trim 5 or 5A | |||||

| 12 | 316 and hard-faced | Note d | 18Cr-8Ni Mo | A351 (CF8M) | A182(F316 | AWS A5.9 ER316 | 18Cr-8Ni-Mo | A276-T316 | Note d |

| 3501 | Trim 5 or 5A | NA | NA | See Trim 5 or 5A | |||||

| 13 | Alloy 20 | Note d | 19Cr-29N | A351 (CN7M) |

B462 | AWS A59 ER320 | 19Cr-29N | B473 | Note d |

| 14 | Alloy 20 and hard-faced | Note d | 19Cr-29Ni | A351 (CN7M) | B473 | AWS A5.9 ER320 | 19Cr-29Ni | B473 | Note d |

| 3501 | Trim 5 or 5A | NA | NA | See Trim 5 or 5A | |||||

| 15 | Hard-faced | 350 e | CoCr-A 9 | NA | NA | AWS 5.13 ECO Cr-A | 18Cr-8Ni | A276-T304 | Note d |

| 16 | Hard-faced | 350 e | CoCr-A g | NA | NA | AWS 5.13 Eco Cr-A | 18Cr-8Ni-Mo | A276-T316 | Note d |

| 17 | Hard-faced | 350 | CoCr-A 9 | NA | NA | AWS 5.13 Eco Cr-A | 18Cr-10Ni- Cb | A276-T347 | Note d |

| 18 | Hard-faced | 350 | CoCr-A g | NA | NA | AWS 5.13 Eco Cr-A | 9Cr-29Ni | B473 | Note d |

| 19 | Nickel o | Note d | Ni alloy | MFG standard o | MFG standard o | MEG standard | Ni alloy° | MFG standard ° | Note d |

| 19A | Alloy 625 | Note d | 22Cr-58Ni | ASTM A494 (CW6MC) | ASTM R564 UNS N06625 |

AWS A5.14 ERNi GrMo-3 |

22Cr-58Ni | ASTM B564 UNS N06625 |

Note d |

| 19B | Alloy C276 | Note d | 15Cr-54N | ASTM A494 (CW2M) | ASTM B564 UNS N10276 | AWS A5.14 ERNiCrMo-4 | 15Cr-54N | ASTM B564 UNS N10276 | Note d |

Table 12—API 602 Nominal Seating Surfaces, Stem, or Weld Deposited Materials and Hardness (Continued)

| Trim No. (CN) | Nominal Trim | Seating Surface Hardness (HB) Min.a | Seating Surface Material Type b | Seating Surface Typical Specifications Grade | Stem | ||||

| Cast | Forged | Welded m | Material Type b | Typical Specifications Type | Stem Hardness (HB) | ||||

| 19C | Alloy 825 | Note d | 21.5Cr- 42Ni | ASTM A494 (CU5M CuC) | ASTM B564 UNS NO8825 | AWS A5.14 =RNiCrMo-3 | 21.5Cr-42Ni | ASTM B564 UNS N08825 |

Note d |

| 20 | Nickel and hard-faced | Note d | Ni Alloy | MFG standard° | MFG standard o | NA | Ni Alloy⁰ | MFG standard | Note d |

| 350 i | CoCr-A9 | NA | NA | AWS 5.13 ECoCr-A AWS 5.21 ERCoCr-A | |||||

| 20A | Alloy 625 and hard-faced | Note d | 22Cr-58Ni | ASTM A494 CW6MC) | ASTM B564 UNS N06625 | AWS A5.14 =RNiCrMo-3 | 22Cr-58Ni | ASTM B564 UNS N06625 |

Note d |

| 350 | CoCr-A g | NA | NA | AWS 5.13 ECoCr-A AWS 5.21 ERCoCr-A | |||||

| 20B | Alloy C276 and hard-faced | Note d | 15Cr-54Ni | ASTM A494 (CW2M) | ASTM B564 UNS N10276 | AWS A5.14 ERNiCrMo-4 | 15Cr-54Ni | ASTM B564 UNS N10276 |

Note d |

| 350 | CoCr-A g | NA | NA | AWS 5.13 EcoCr-A or AWS 5.21 EcoCr-A | |||||

| 20C | Alloy 825 and hard-faced | Note d | 21.5Cr- 42Ni | ASTM A494 (CU5MCuC) | ASTM B564 UNS N08825 | AWS A5.14 ERNi CrMo-3 | 21.5Cr-42Ni | ASTM B564 UNS N08825 |

Note d |

| 350 i | CoCr-A g | NA | NA | AWS 5.13 ECoCr-A or AWS 5.21 ECoCr-A | |||||

Table 12—API 602 Nominal Seating Surfaces, Stem, or Weld Deposited Materials and Hardness (Continued)

| Trim No (CN) | Nominal Trim | Seating Surface Hardness (HB) Min.a | Seating Surface Materia Type b | Seating Surface Typical Specifications Grade | Stem | ||||

| Cast | Forged | Welded m | Material Type b | Typica Specifications Type | Stem Hardness (HB) | ||||

| 21 | Hard-faced o | 350 e | CoCr-A g | NA | NA | AWS 5.13 ECoCr-A AWS 5.21 ERCoCr-A | Ni alloy° | MFG standard o | Note d |

| NOTE Cr=Chromium;Ni=Nickel;Co =Cobalt;Cu=Copper;NA =Not Applicable | |||||||||

| a HB(formerly BHN)is the symbol for the Brinell hardness per ASTM E10 b Free machining grades of 13Cr are prohibited. c Body and closure element seating surfaces should be 250 HB minimum with a 50 HB minimum differential between the body and closure element seating surfaces d Manufacturer's standard hardness. e Differential hardness between the body and closure element seating surfaces is not required. f Case hardness by nitriding to a thickness of 0.13 mm(0.005 in.)minimum. g This classification includes such trademark materials as Stellite 6TM*,Stoody 6TM*and Wallex 6TM*,the use of CoCr-E(Stellite 21TM *)or equal is an acceptable substitution for CoCr-A in globe and check valves h Manufacturer's standard hardfacing with a maximum iron content of 25 %. i Hardness differential between the body and closure element seating surfaces shall be the manufacturer's standard. J Not used k Manufacturer's standard with 30 Ni minimum. l Not used m Not used n Not used o Trim materials,including stem and base material for HF trim items,shall have a corrosion resistance,and temperature limit at least equal to the valve body's corrosion resistance and pressure temperature rating *Monel is used strictly as an example of any nickel-copper alloy 400 matching UNS N04400 specifications.API standards do not endorse or require the purchase or use of proprietary products or services as a condition of implementing the standard | |||||||||

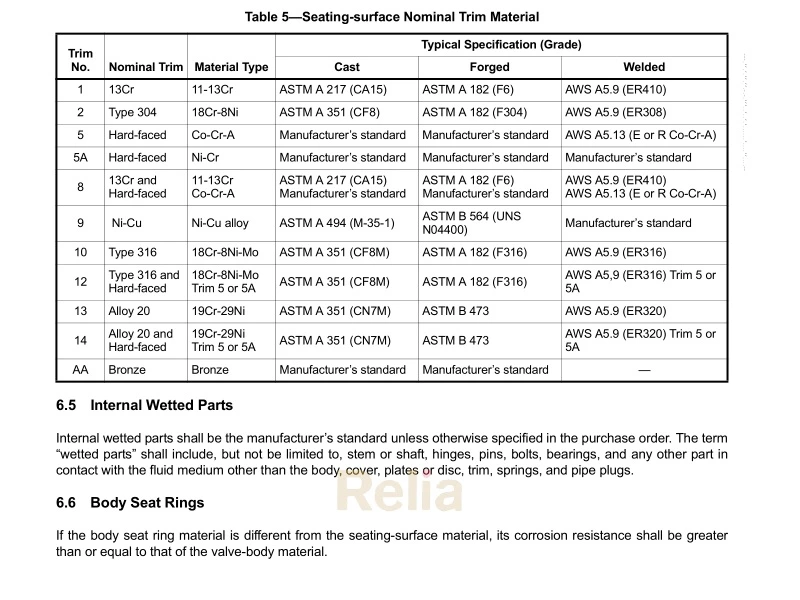

Trim Materials

Trim items include the stem, the wedge/disc seating surfaces, and the body or seat ring seating surfaces. The valve trim for check valves shall consist of the seating surface of the closure element and body or seat ring. The trim combination number (CN) identifies both the stem material and the associated seating surface material. Except as noted in 6.1 .2 and 6.1 .3 or when otherwise agreed between the purchaser and manufacturer, the trim material combinations shall be in accordance with Table 1 2.

Trims of free machining materials, e.g., 1 3Cr steel grades containing additions of elements such as lead, selenium, or sulfur to enhance machinability, are intentionally not listed in Table 1 2. They may be used only when specified by the purchaser, in which case they shall be identified by the appropriate trim number from Table 1 2 plus 1 00. The affected trim CN numbers would thus be identified as, for example, CN 1 01 , 1 04, 1 05, 1 06, 1 07, and 1 08. Correspondingly, hard-facing or other material overlays shall not be applied to free machining grades of base materials unless so specified by the purchaser.