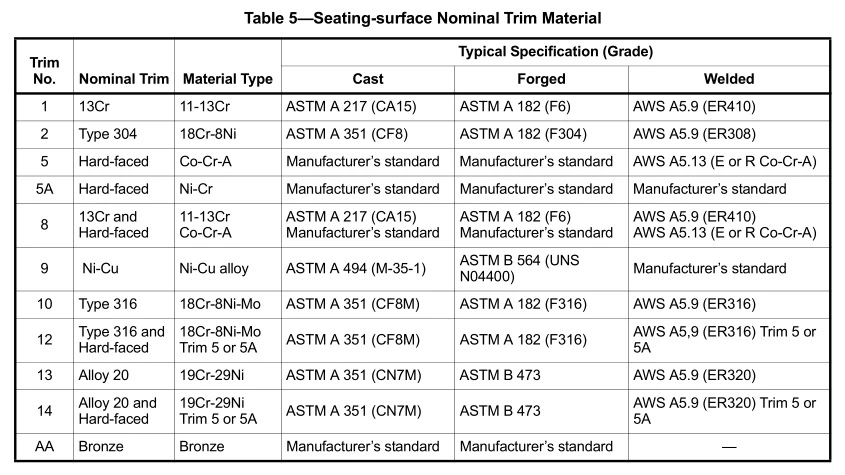

API 594 Trim Material Chart

API 594 trim material no. 1, 5, 5A, 8, 9, 10, 12, 13, 14, AA, for body seating surfaces; plate or discseating surfaces.

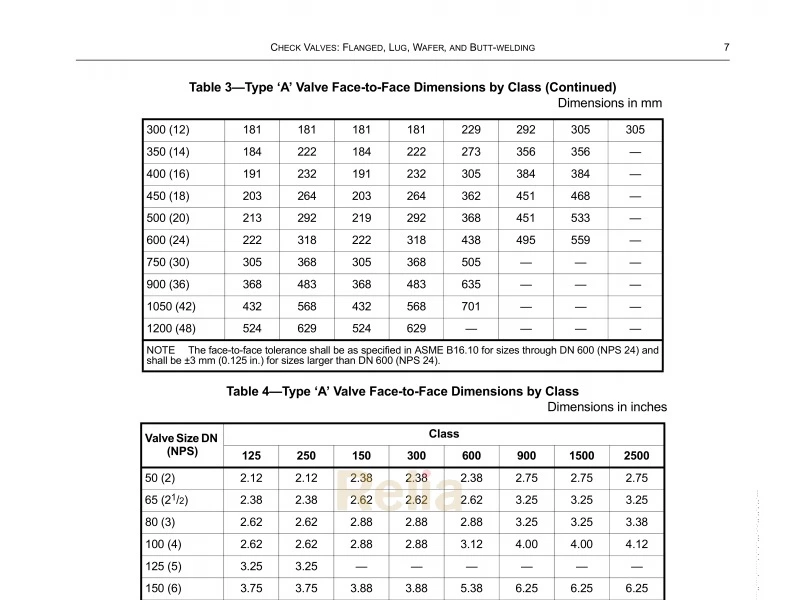

Table 5—API 594 Seating-surface Nominal Trim Material

| Trim No. | Nominal Trim | Material Type | Typical Specification (Grade) | ||

| Cast | Forged | Welded | |||

| 1 | 13Cr | 11-13Cr | ASTM A 217 (CA15) | ASTM A 182 (F6) | AWS A5.9(ER410) |

| 2 | Type 304 | 18Cr-8Ni | ASTM A 351(CF8) | ASTM A 182 (F304) | AWS A5.9 (ER308) |

| 5 | Hard-faced | Co-Cr-A | Manufacturer's standard | Manufacturer's standard | AWS A5.13 (E or R Co-Cr-A) |

| 5A | Hard-faced | Ni-Cr | Manufacturer's standard | Manufacturer's standard | Manufacturer's standard |

| 8 | 13Cr and Hard-faced | 11-13Cr Co-Cr-A | ASTM A217 (CA15) Manufacturer's standard | ASTM A 182(F6) Manufacturer's standard | AWS A5.9 (ER410) AWS A5.13 (E or R Co-Cr-A) |

| 9 | Ni-Cu | Ni-Cu alloy | ASTM A 494(M-35-1) | ASTM B 564 (UNS N04400) | Manufacturer's standard |

| 10 | Type 316 | 18Cr-8Ni-Mo | ASTM A351 (CF8M) | ASTM A 182 (F316) | AWS A5.9 (ER316) |

| 12 | Type 316 and Hard-faced | 18Cr-8Ni-Mo Trim 5 or 5A | ASTM A 351 (CF8M) | ASTM A 182 (F316) | AWS A5,9 (ER316)Trim 5 or 5A |

| 13 | Alloy 20 | 19Cr-29Ni | ASTM A 351 (CN7M) | ASTM B 473 | AWS A5.9 (ER320) |

| 14 | Alloy 20 and Hard-faced | 19Cr-29Ni Trim 5 or 5A | ASTM A 351 (CN7M) | ASTM B 473 | AWS A5.9 (ER320)Trim 5 or 5A |

| AA | Bronze | Bronze | Manufacturer's standard | Manufacturer's standard | —— |

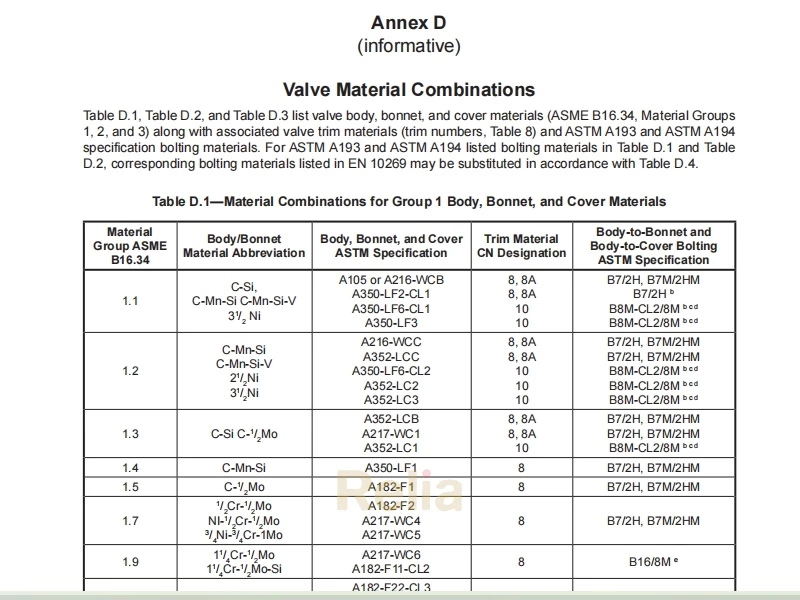

6 Material

6.1 Bodyand Cover

The body of Type'A valves and the body and cover of Type 'B' valves shall be made of a material conforming to a purchaserselected material specification listed in the applicable ASME standard as referenced in 4.1.

6.2 Plate and Disc

Plate or disc shall be made of a material whose corrosion resistance is greater than or equal to that of the valve body.

API 594 Trim Material Chart

6.3 Cover Gasket (Type‘B’Valves)

6.3.1 The cover flange gasketshall be:

一 solid metal,corrugated or flat;

一 filled metal jacketed,corrugated or flat;

一 metal ring joint;

— spiral-wound metal gasket with filler and a centering/compression ring;

一 spiral-wound metal gasket with filler,to be used in a body to cover joint design that provides gasket compression control.

For Class 150,the following are also acceptable:

一 corrugated metal insert with graphite facings;

一 when approved by the purchaser,flexible graphite sheet,reinforced with a stainless steel flat,perforated,tanged, or corrugated insert equipped with annular containment rings.

6.3.2 The metallic portion of the gasket exposed to the service environment shall be made of a material that has corrosion resistance at least equal to the body.

6.3.3 Unless otherwise specified in the purchase order,the gasket shall be suitable for the pressure rating of the valve within a valve design temperature range from-29 ℃ (-20 °F)to 538 ℃(1000 °F).

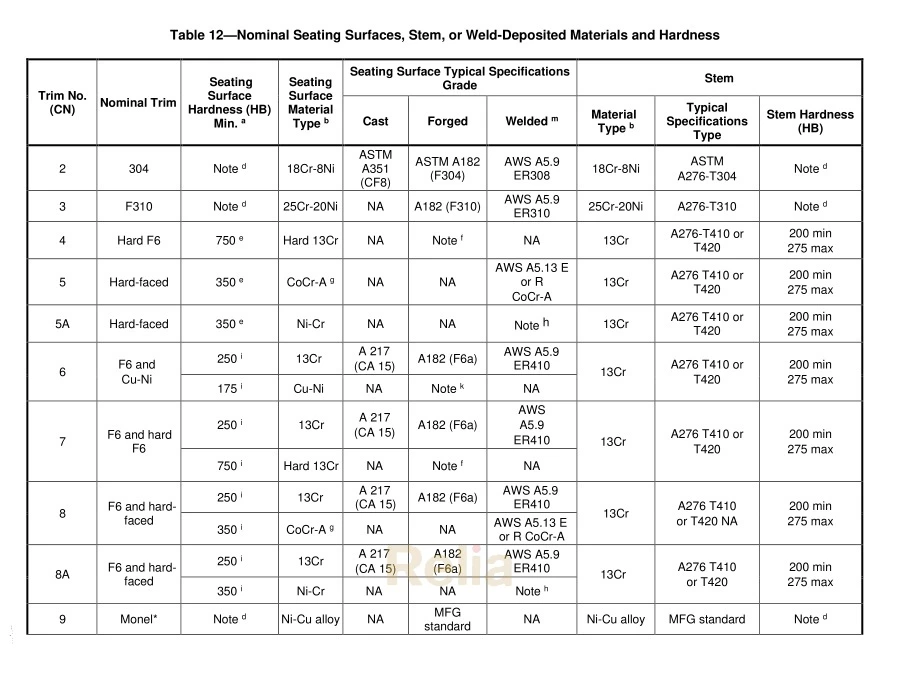

6.4 Trim

6.4.1 The trim includes the following:

一 body seating surfaces;

一 plate or discseating surfaces.

6.4.2 Metallic seating surface materialshall be manufacturer's standard which may be the same as the body material.Where specific trim is requested,it shall be as shown in Table 5.The typical specifications in Table 4 represent some acceptable grades.Ni-Cr materials (Trim 5A)shall have manufacturer's standard hard facing with a maximum iron content of 25 %.

6.4.3 Resilient seat material,when required shall be specified by the purchaser and if located in the body there shall not be an overlay in the seat area unless otherwise specified in the purchase order.

6.5 Internal Wetted Parts

Internal wetted parts shall be the manufacturer's standard unless otherwise specified in the purchase order.The term “wetted parts”shall include,but not be limited to,stem or shaft,hinges,pins,bolts,bearings,and any other part in contact with the fluid medium other than the body,cover,plates or disc,trim,springs,and pipe plugs.

6.6 BodySeat Rings

If the body seat ring material is different from the seating-surface material,its corrosion resistance shall be greater than or equal to that of the valve-body material.

6.7 Springs

Unless otherwise specified in the purchase order,the spring materialshall be as follows:

一 for design temperatures 315 ℃(600°F),and above,spring material shall be Nickel-chromium alloy UNS N07750;

一 for temperatures below 315 ° ℃(600 °F),the spring materialshall be the manufacturer's standard.

6.8 PipePlugs(Pin Retainers)

Any pipe plugs used shall be solid and shall have the same nominal chemical composition and material properties as the valve body