API 594 Face to Face Dimensions

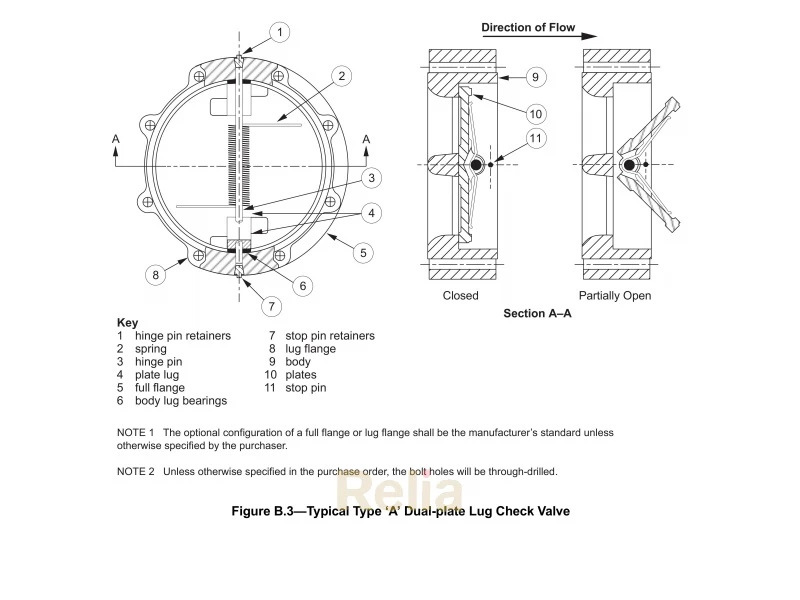

API 594 check valve face to face dimensions for Type 'A' check valves including check valve types: wafer, lug, or double flanged; single plate or dual plate.

Type 'A' check valves are short face-to-face as defined in Table 3 and Table 4 and can be: wafer, lug, or double flanged; single plate or dual plate; gray iron, ductile iron, steel, nickel alloy, or other alloy designed for installation between Classes 125 and 250 cast iron flanges as specified in ASME B16.1, between Classes 150 and 300 ductile iron flanges as specified in ASME B16.42, between Classes 150 and 2500 steel flanges as specified in ASME B16.5, and between Classes 150 and 600 steel pipeline flanges as specified in MSS SP-44 or steel flanges as specified in ASME B16.47.

Flange faces with ring-joint grooves shall conform to the dimensions shown in either ASME B16.5 or ASME B16.47, as applicable.

Flange facing finishes shall be:

一 Type 'A' valves only: gray iron and ductile iron valves shall be finished as specified in MSS SP-6;

一 Type 'A' and Type 'B' valves: steel, nickel-alloy, and other alloy valves shall be finished as specified in ASME B16.5.

Table 3—Type 'A' Valve Face-to-Face Dimensions by Class

Dimensions in mm

| Valve Size DN (NPS) |

Class | |||||||

| 125 | 250 | 150 | 300 | 600 | 900 | 1500 | 2500 | |

| 50 (2) | 54 | 54 | 60 | 60 | 60 | 70 | 70 | 70 |

| 65 (21/2) | 60 | 60 | 67 | 67 | 67 | 83 | 83 | 83 |

| 80 (3) | 67 | 67 | 73 | 73 | 73 | 83 | 83 | 86 |

| 100 (4) | 67 | 67 | 73 | 73 | 79 | 102 | 102 | 105 |

| 125 (5) | 83 | 83 | — | — | — | — | — | — |

| 150 (6) | 95 | 95 | 98 | 98 | 136 | 159 | 159 | 159 |

| 200 (8) | 127 | 127 | 127 | 127 | 165 | 206 | 206 | 206 |

| 250 (10) | 140 | 140 | 146 | 146 | 213 | 241 | 248 | 254 |

Table 3—Type 'A' Valve Face-to-Face Dimensions by Class (Continued)

Dimensions in mm

| 300 (12) | 181 | 181 | 181 | 181 | 229 | 292 | 305 | 305 |

| 350 (14) | 184 | 222 | 184 | 222 | 273 | 356 | 356 | — |

| 400 (16) | 191 | 232 | 191 | 232 | 305 | 384 | 384 | — |

| 450 (18) | 203 | 264 | 203 | 264 | 362 | 451 | 468 | — |

| 500 (20) | 213 | 292 | 219 | 292 | 368 | 451 | 533 | — |

| 600 (24) | 222 | 318 | 222 | 318 | 438 | 495 | 559 | — |

| 750 (30) | 305 | 368 | 305 | 368 | 505 | — | — | — |

| 900 (36) | 368 | 483 | 368 | 483 | 635 | — | — | — |

| 1050 (42) | 432 | 568 | 432 | 568 | 701 | — | — | — |

| 1200 (48) | 524 | 629 | 524 | 629 | — | — | — | — |

| NOTE The face-to-face tolerance shall be as specified in ASME B16.10 for sizes through DN 600 (NPS 24) and shall be±3 mm (0.125 in.)for sizes larger than DN 600 (NPS 24) |

||||||||

Table 4—Type 'A'Valve Face-to-Face Dimensions by Class

Dimensions in inches

| Valve Size DN (NPS) |

Class | |||||||

| 125 | 250 | 150 | 300 | 600 | 900 | 1500 | 2500 | |

| 50 (2) | 2.12 | 2.12 | 2.38 | 2.38 | 2.38 | 2.75 | 2.75 | 2.75 |

| 65 (21/2) | 2.38 | 2.38 | 2.62 | 2.62 | 2.62 | 3.25 | 3.25 | 3.25 |

| 80 (3) | 2.62 | 2.62 | 2.88 | 2.88 | 2.88 | 3.25 | 3.25 | 3.38 |

| 100 (4) | 2.62 | 2.62 | 2.88 | 2.88 | 3.12 | 4.00 | 4.00 | 4.12 |

| 125 (5) | 3.25 | 3.25 | — | — | — | — | — | — |

| 150 (6) | 3.75 | 3.75 | 3.88 | 3.88 | 5.38 | 6.25 | 6.25 | 6.25 |

| 200 (8) | 5.00 | 5.00 | 5.00 | 5.00 | 6.50 | 8.12 | 8.12 | 8.12 |

| 250 (10) | 5.50 | 5.50 | 5.75 | 5.75 | 8.38 | 9.50 | 9.75 | 10.00 |

| 300 (12) | 7.12 | 7.12 | 7.12 | 7.12 | 9.00 | 11.50 | 12.00 | 12.00 |

| 350 (14) | 7.25 | 8.75 | 7.25 | 8.75 | 10.75 | 14.00 | 14.00 | — |

| 400 (16) | 7.50 | 9.12 | 7.50 | 9.12 | 12.00 | 15.12 | 15.12 | — |

| 450 (18 | 8.00 | 10.38 | 8.00 | 10.38 | 14.25 | 17.75 | 18.44 | — |

| 500 (20) | 8.38 | 11.50 | 8.62 | 11.50 | 14.50 | 17.75 | 21.00 | — |

| 600 (24) | 8.75 | 12.50 | 8.75 | 12.50 | 17.25 | 19.50 | 22.00 | — |

| 750 (30) | 12.00 | 14.50 | 12.00 | 14.50 | 19.88 | — | — | — |

| 900 (36) | 14.50 | 19.00 | 14.50 | 19.00 | 25.00 | — | — | — |

| 1050 (42) | 17.00 | 22.38 | 17.00 | 22.37 | 27.61 | — | — | — |

| 1200 (48) | 20.62 | 24.75 | 20.62 | 24.75 | — | — | — | — |

| NOTE The face-to-face tolerance shall be as specified in ASME B16.10 for sizes through DN 600 (NPS 24) and shall be±3 mm(0.125 in.)for sizes larger than DN 600 (NPS 24). |

||||||||